DTF Printing is a game-changer for clothing manufacturing, offering precise, vibrant direct printing on fabrics without costly screen setups. Streamlining production for small batches to large scales, it ensures quality and supports diverse fabric types. Integrating DTF into workflows with best practices enhances productivity, enabling businesses to meet customer demands quickly and efficiently.

In today’s print industry, integrating DTF (Direct-To-Form) Printing can revolutionize your workflows. This article guides you through the process of adopting DTF Printing into existing operations, offering a comprehensive overview starting with understanding its basics and benefits. We explore strategies for seamless integration, ensuring optimal results. Learn best practices to streamline your workflows, enhance efficiency, and unlock the full potential of DTF Printing.

- Understanding DTF Printing: Basics and Benefits

- Integrating DTF into Your Current Operations

- Best Practices for Seamless Workflows with DTF

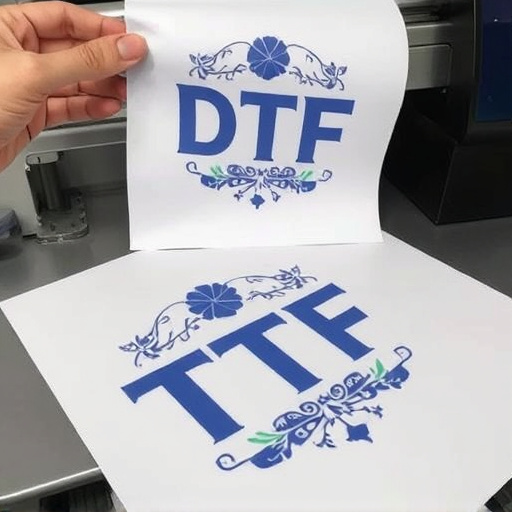

Understanding DTF Printing: Basics and Benefits

DTF (Direct-to-Fabric) Printing is a game-changing technology that allows for precise and vibrant printing directly onto fabrics, offering a seamless integration into existing workflows for clothing manufacturers and custom tee printers. This method involves transferring designs from custom sheets to garments using heat and pressure, resulting in high-quality, long-lasting prints.

The benefits of DTF Printing are numerous: it streamlines the production process by eliminating the need for costly screen printing set-ups, making it an efficient choice for both small-batch and large-scale production. DTF transfers ensure consistent quality across each unit, perfect for creating Custom graphic tees with intricate designs and vibrant colors. This technology also supports a wide range of fabric types, allowing printers to cater to various garment preferences and offering a unique selling point in the market.

Integrating DTF into Your Current Operations

Integrating DTF (Direct to Fiber) printing into your existing workflows can seem daunting at first, but with a strategic approach, it becomes a seamless addition. Start by assessing your current operations and identifying where DTF can fill gaps or enhance productivity. For instance, if you’re a clothing brand, consider implementing DTF for custom designs on t-shirts, allowing for faster turnaround times compared to traditional printing methods. This technology enables the direct application of designs to various fabrics, streamlining your production process.

By integrating DTF printing, you can automate the transfer process, eliminating manual steps and reducing human error. A heat press is a crucial tool in this method, ensuring precise and long-lasting dtf transfers. This efficient workflow not only saves time but also enhances the quality of your products. Whether you’re a small business or an established enterprise, embracing DTF printing can revolutionize your operations, enabling you to meet customer demands promptly and with exceptional results.

Best Practices for Seamless Workflows with DTF

To ensure seamless integration of Direct to Fabric (DTF) printing into existing workflows, best practices involve streamlining preparation and post-processing steps. Start by selecting a reliable DTF printer suitable for your project requirements; consider factors like print quality, speed, and ease of use when choosing the best dtf printer. Invest in high-quality materials to avoid issues like smudging or fading later. Standardize on file formats and settings to simplify the workflow; this consistency ensures that designs translate accurately from design software to heat press application.

Designers should familiarize themselves with the specific needs of DTF printing, such as proper scaling and color profiles, to prevent common pitfalls like misaligned prints or off-color outcomes. Efficient file management systems and regular backups are crucial for minimizing delays and ensuring quick turnaround times. By adopting these practices, businesses can enhance productivity while delivering high-quality printed fabrics without disrupting existing operational processes.

Integrating DTF printing into your existing workflows can streamline production processes, enhance creativity, and offer a competitive edge. By understanding the basics and benefits of DTF, adopting it into your operations, and following best practices, you can efficiently harness its capabilities to produce high-quality, on-demand prints. Embrace this innovative technology to stay ahead in the market and elevate your printing game.