DTF (Direct to Fabric) Printing is a cutting-edge method for high-quality fabric printing, allowing designers and businesses to create intricate, vibrant designs on various fabrics. Using specialized water-based inks and equipment, this process involves applying ink directly to the fabric, curing it with UV or heat, and then removing a clear film to leave the design. DTF offers enhanced color vibrancy, durability, and custom on-demand production capabilities, making it popular for fashion designers creating unique apparel. Choosing suitable fabrics like cotton, poly-cotton blends, or synthetics is crucial for achieving optimal print quality and durable end products.

“Unleash your creativity with Direct-to-Fabric (DTF) printing, a game-changing technique revolutionizing apparel design. This article delves into the world of DTF, exploring its fundamentals and offering a comprehensive guide for designers. From understanding the process and suitable fabrics to creative considerations and implementing best practices, we uncover the secrets behind crafting stunning, unique garments. Discover how DTF Printing allows you to bring your vision to life, adding texture, color, and intricate patterns to your designs.”

- Understanding DTF Printing: The Basics

- – Definition and process of Direct-to-Fabric (DTF) printing

- – Types of fabrics suitable for DTF printing

Understanding DTF Printing: The Basics

DTF Printing, or Direct to Fabric Transfer, is a cutting-edge technique revolutionizing apparel design and customization. This innovative process allows for high-quality printing directly onto fabric, offering endless creative possibilities for designers and businesses. By using specialized equipment and inks, DTF enables the creation of intricate designs with vibrant colors and precise details.

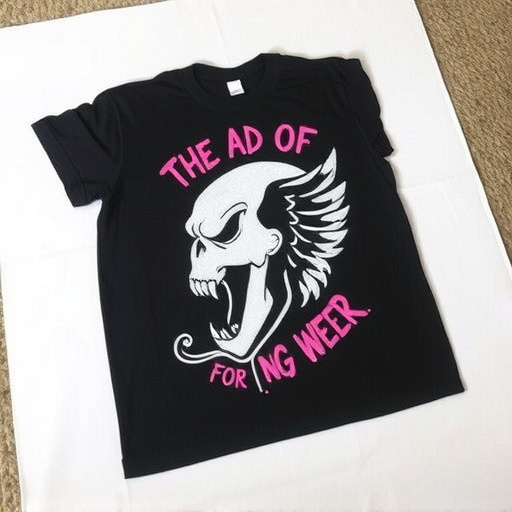

The process starts by applying a thin layer of water-based ink to the fabric, typically cotton or polyester. A clear film is then placed on top, acting as a transfer medium. The design, whether it’s a simple logo or a complex graphic, is printed onto this film using high-resolution printers. Once the ink is cured, the film is carefully peeled away, leaving a precise and long-lasting image on the fabric. This method is particularly popular for creating custom DTF transfers, which can then be applied to various garments, including t-shirts, enabling efficient bulk dft shirt production while maintaining exceptional quality.

– Definition and process of Direct-to-Fabric (DTF) printing

Direct-to-Fabric (DTF) printing is a cutting-edge technique revolutionizing the apparel industry. Unlike traditional methods, DTF directly applies ink to the fabric’s surface, eliminating the need for intermediate transfer materials. This process involves specialized printers that use UV or heat curable inks, allowing designers to create intricate patterns and vivid colors on various fabrics with remarkable precision.

The DTF for Apparel method starts by preparing custom sheets containing heat-sensitive designs. These sheets are then precisely aligned over the garment, typically a t-shirt or hoodie. A heat press is used to fuse the ink onto the fabric, ensuring it becomes permanently bonded. This technique offers numerous advantages, such as enhanced color vibrancy, superior print durability, and the ability to produce custom, on-demand apparel with intricate designs, making it a favorite among both fashion designers and small businesses looking to create unique, high-quality garments.

– Types of fabrics suitable for DTF printing

When designing apparel with DTF (Direct-to-Fabric) printing techniques, the choice of fabric plays a pivotal role in achieving exceptional print quality and final product durability. The most suitable fabrics for DTF printing are those that offer a smooth surface for optimal ink adhesion, good absorption properties, and a flexible texture to withstand the printing process without deforming or cracking. Commonly used materials include cotton, poly-cotton blends, and certain synthetic fabrics like polyester and nylon. These fabrics ensure that the vibrant colors and intricate designs of DTF prints are accurately reproduced while providing comfort and longevity to the garments.

For custom dtf transfers, it’s essential to select fabrics compatible with dtf heat transfer paper. This specialized paper facilitates the direct application of design elements onto fabric through heat and pressure, making it a versatile option for creating unique apparel designs. The versatility of DTF printing allows designers to cater to a wide range of fabric types, from lightweight t-shirts to heavier denim jackets, ensuring that each garment becomes a canvas for artistic expression while maintaining superior comfort and style.

Designing apparel with DTF printing techniques offers a versatile and efficient method for creating unique, high-quality garments. By understanding the direct-to-fabric (DTF) printing process and selecting suitable fabrics, designers can unlock endless creative possibilities. This innovative approach allows for precise, detailed prints that enhance the overall aesthetic and durability of clothing pieces, making DTF printing a valuable asset in the modern fashion industry.