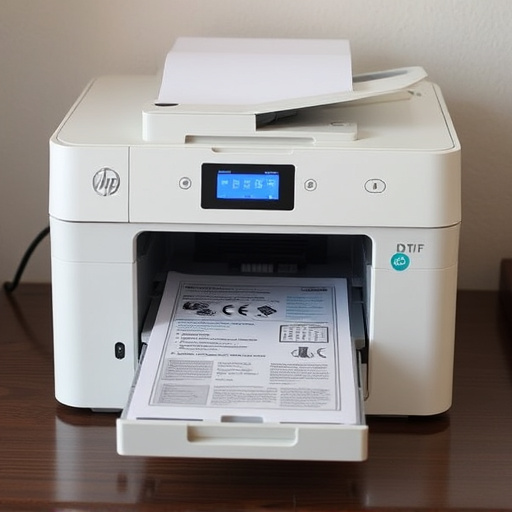

DTF Printing (Direct to Fabric Printing) is a revolutionary process in the textile industry, enabling high-quality, customizable designs on various fabrics with fast production times and vibrant colors. This modern method bypasses traditional printing needs for screens or plates by directly applying ink via a specialized heat press. Ideal for custom clothing, home decor, and promotional items, DTF Printing's versatility caters to diverse industries and individual creators seeking unique, personalized printed products.

“Unleashing a revolution in the printing industry, DTF Printing (Direct-To-Final Printing) is reshaping the way we produce high-quality, custom designs. This cutting-edge technology offers unparalleled precision and versatility, enabling intricate patterns and vibrant colors on diverse materials.

In this article, we’ll explore the innovative process of DTF Printing, its benefits for various applications, and why it’s fast becoming a game-changer in manufacturing and design.”

- Understanding DTF Printing: A New Age of Print Technology

- The Process Behind DTF Printing: From Design to Final Product

- Benefits and Applications: Why DTF Printing is a Game Changer

Understanding DTF Printing: A New Age of Print Technology

DTF Printing, short for Direct to Fabric Printing, is revolutionizing the textile industry with its advanced and precise printing technology. This innovative method has introduced a new age in print technology, enabling the creation of high-quality, customizable designs on various fabric types. Unlike traditional printing techniques, DTF Printing directly applies ink to the fabric’s surface, eliminating the need for intermediate materials like screens or plates.

The process involves a specialized heat press that precisely controls temperature and pressure to transfer ink onto the fabric. This technology ensures fast production times, making it an efficient solution for custom clothing, home decor, and promotional products. DTF Printing’s versatility allows for intricate designs with vibrant colors, appealing to a wide range of industries and individual creators seeking unique and personalized printed items, from dtf prints to custom-made garments.

The Process Behind DTF Printing: From Design to Final Product

The process of DTF (Direct to Garment) Printing involves a series of precise steps that bring digital designs to life on various materials, especially fabrics. It all starts with a designer creating or obtaining a print-ready design. This graphic is then prepared for printing using specialized software, ensuring the correct colors and resolution. Once ready, the DTF printer applies ink directly onto the garment’s surface through a fine nozzle, mimicking traditional screen printing methods but with greater flexibility.

After printing, the ink needs to set and cure properly. This is achieved through a combination of heat and pressure, typically using a heat press. The heat press applies controlled temperature and pressure to the printed garment, fusing the ink into the fabric fibers, resulting in a permanent and vibrant image. Finally, the cured design is carefully inspected to ensure it meets quality standards, and the final product is packaged for shipping or further customization, such as adding custom sheets for heat pressing additional designs onto garments.

Benefits and Applications: Why DTF Printing is a Game Changer

DTF Printing, short for Direct-To-Film Printing, is revolutionizing the way custom designs are applied to various products, from apparel to promotional items. Its benefits are numerous and far-reaching, making it a game-changer in several industries. One of its key strengths lies in its ability to produce high-quality, vibrant prints directly on film, eliminating the need for intermediate transfer materials. This not only streamlines the production process but also ensures that colors remain rich and accurate from design to final product.

Moreover, DTF Printing offers unparalleled versatility. It’s ideal for creating custom dtf transfers that can be applied to a wide range of items, including popular choices like hoodies and other apparel. The direct to film printer facilitates quick turnarounds and small batch orders, making it suitable for both bulk production and on-demand printing scenarios. This flexibility has fostered innovation, allowing businesses to cater to diverse customer preferences and trends in the market, all while maintaining exceptional print quality.

DTF printing, or Direct-to-Fabric printing, has emerged as a revolutionary technology, offering unprecedented versatility and quality in the world of textile design. By streamlining the process from design to final product, DTF allows for complex, vibrant patterns and images to be applied directly to various fabrics with remarkable precision and speed. Its benefits extend across numerous industries, from fashion and home decor to signage and promotional products, making it a game-changer that’s here to stay.